3.0万t/d生活污水处理工程设计

摘要

在本次毕业设计的题目为某地区城市生活污水处理厂的工程设计(3.0t/d)。本次任务是完成该地区污水处理设计。

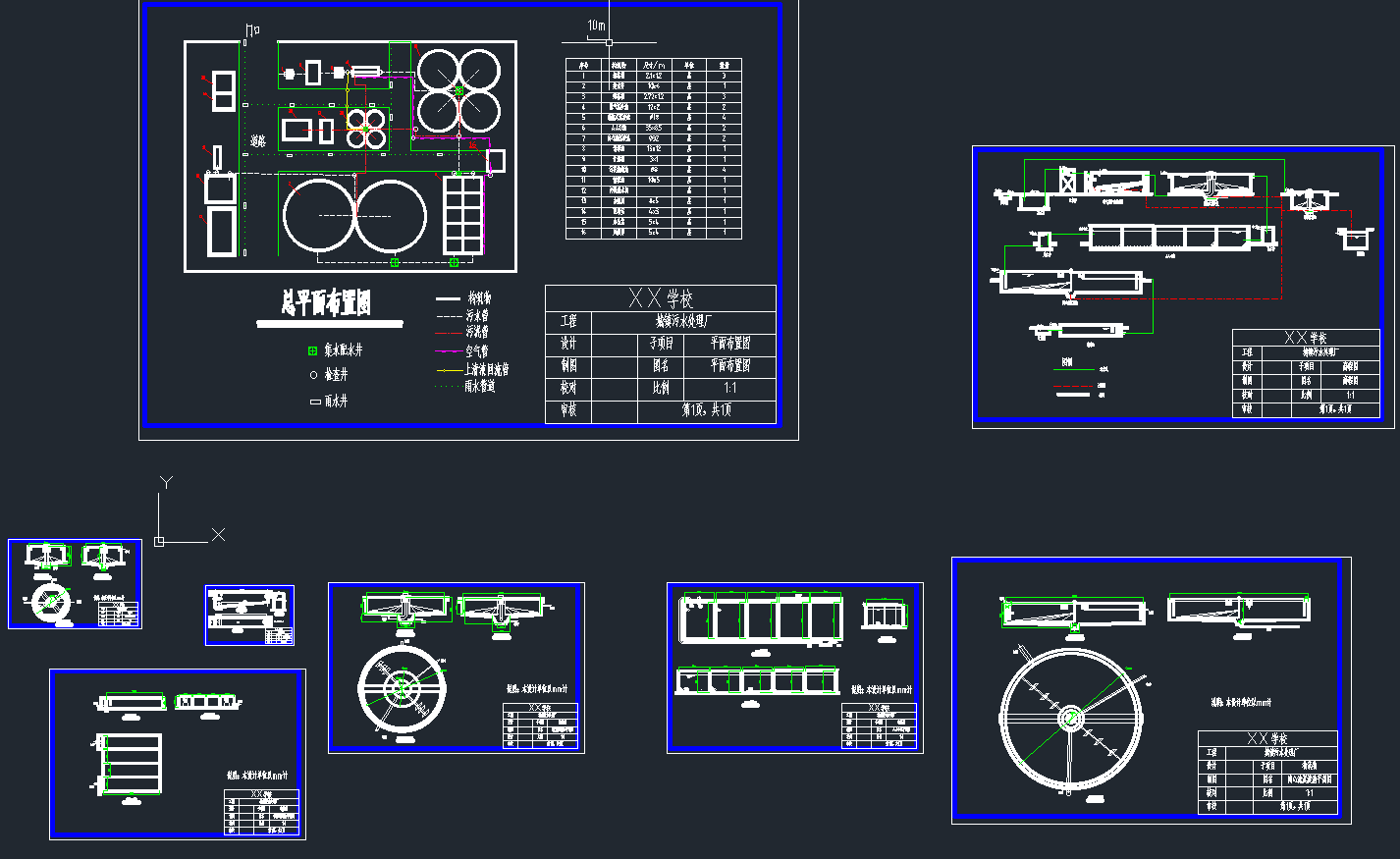

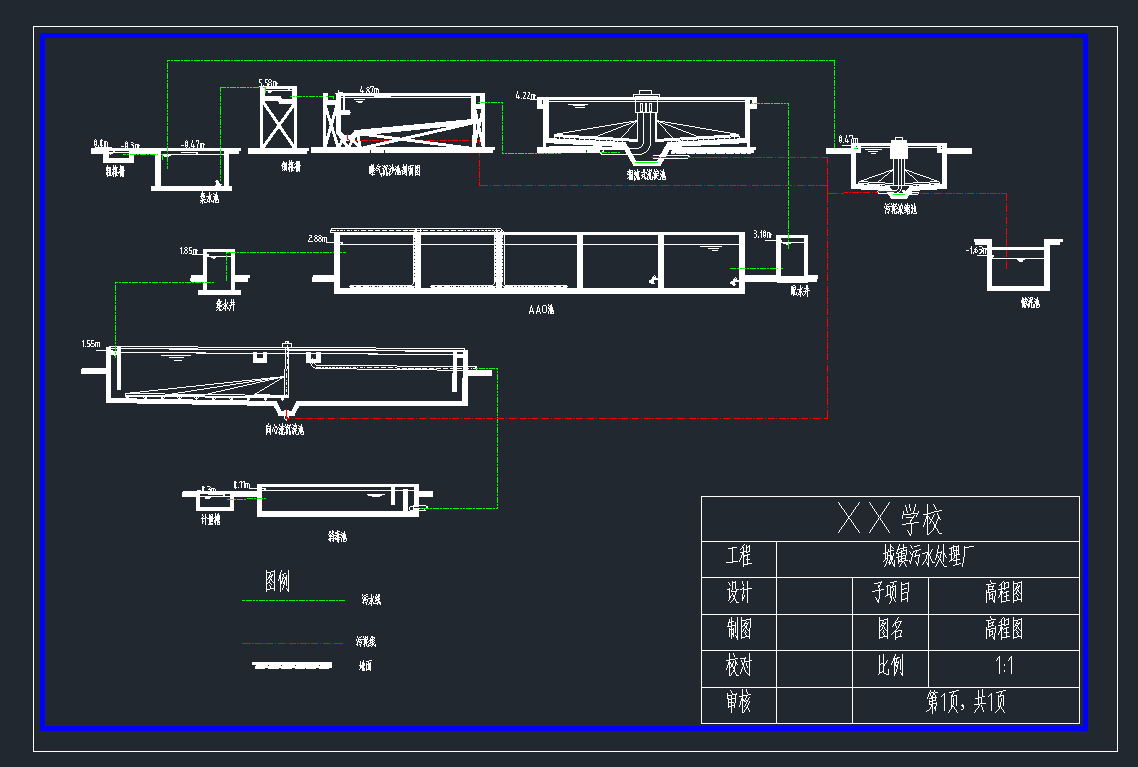

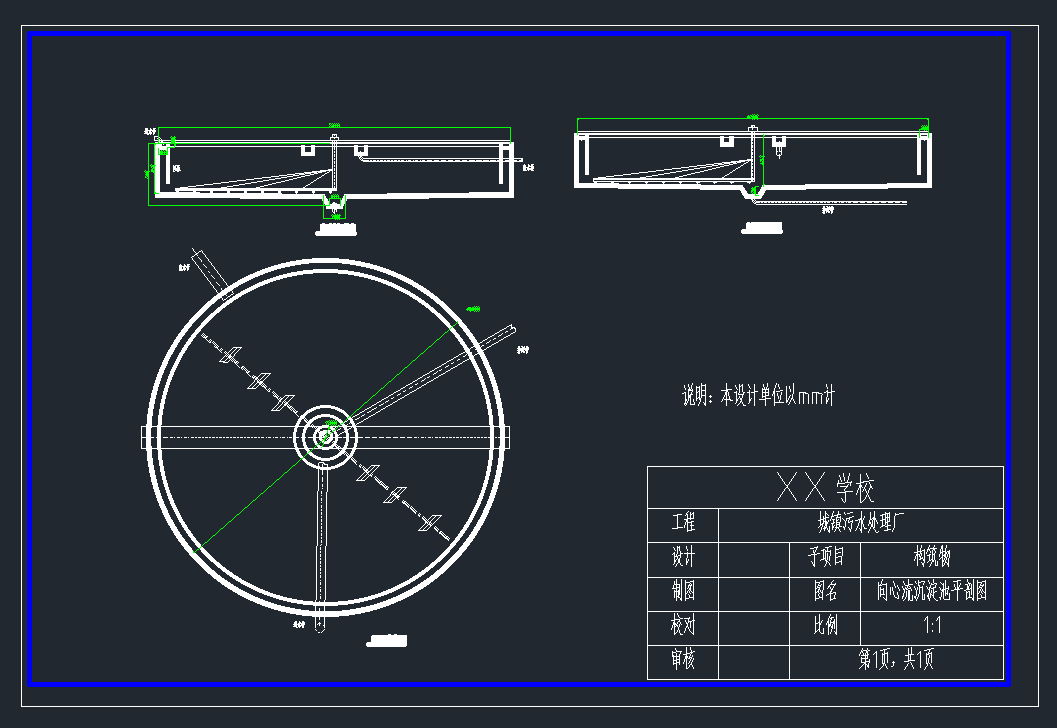

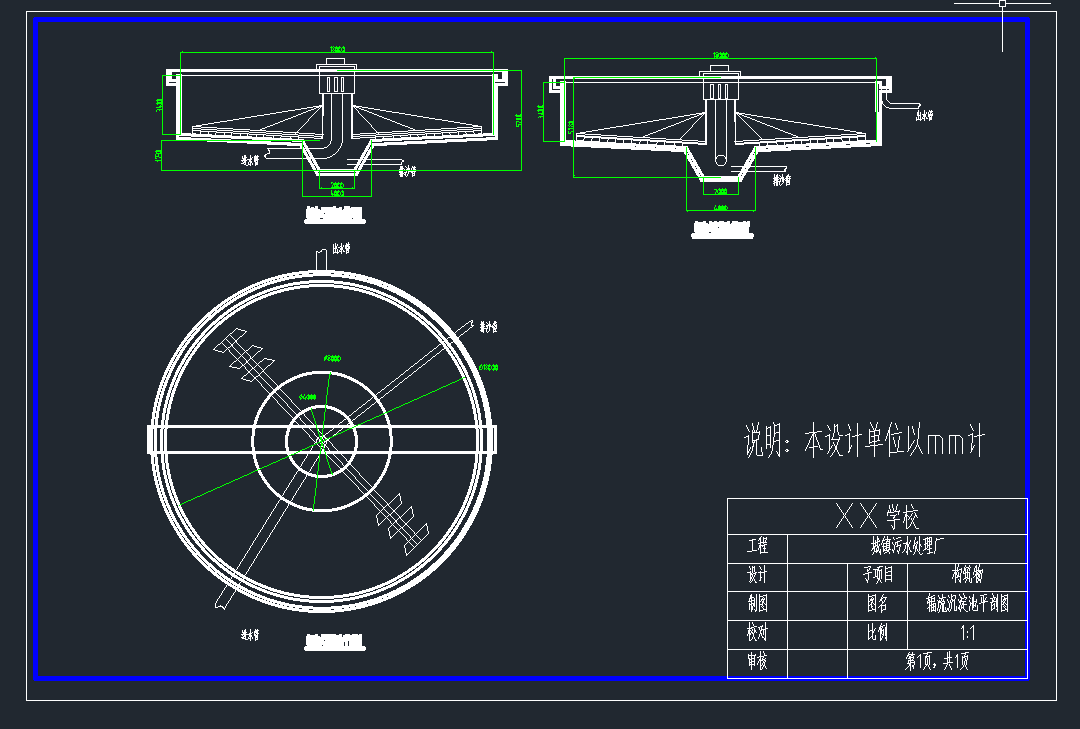

在本次设计中要完成设计说明书一份,污水处理厂厂区的平面布置图一份,污水处理设施及污泥处理设施的高程图一份。并给出单项处理构筑物的剖面图和大样图。

该污水处理厂的处理量为3万吨每天。

本次污水厂采取A2/O工艺处理污水,A2/O生物处理部分由厌氧池、缺氧池、好氧池。厌氧池主要是释放生活污水中的磷含量,缺氧池主要功能是通过反硝化除去污水中的氮元素,而好氧池的作用是去除BOD和硝化以及吸收磷。

该污水处理厂的污水处理流程为:从粗格栅到污水泵房再到细格栅,进入曝气沉砂池,接着进入初沉池,再进入A2/O生物池,再进入向心辐流式二沉池,再进入接触消毒池,最后再出水到河中。污泥处理的流程:从A2/O出来的剩余进入集泥配水井,在进入污泥泵房到污泥浓缩池中,再进入储泥室,到脱水机房进行脱水,最后外运处置。

关键词:A2/O脱氮除磷工艺 工程设计 生活污水 污泥处理

Abstract

The topic of this graduation project is the engineering design of the municipal sewage treatment plant in a certain area (3.0T / D). This task is to complete the design of sewage treatment in this area.

In this design, one copy of design specification, one copy of layout plan of sewage treatment plant and one copy of elevation drawing of sewage treatment facilities and sludge treatment facilities shall be completed. Section and detail drawing of single treatment structure are given.

The capacity of the sewage treatment plant is 30000 tons per day. The sewage treatment plant adopts A2 / O process for sewage treatment, and the A2 / O biological treatment part consists of anaerobic tank, anoxic tank and aerobic tank. The main function of anoxic tank is to remove nitrogen through denitrification, while the function of aerobic tank is to remove BOD, nitrification and phosphorus absorption.

The sewage treatment process of the sewage treatment plant is as follows: from the coarse grid to the sewage pump room and then to the fine grid, enter the aeration grit chamber, then enter the primary sedimentation tank, then enter the A2 / O biological tank, then enter the centripetal radial flow secondary sedimentation tank, then enter the contact disinfection tank, and finally the water will be discharged into the river. Sludge treatment process: the surplus from A2 / O will enter the sludge collection and distribution well, enter the sludge pump room to the sludge concentration tank, then enter the sludge storage room to the dehydration machine room for dehydration, and finally be transported out for disposal.

Key words: A2 / O denitrification and phosphorus removal process engineering design domestic sewage sludge treatment

第一章 设计概论

项目规划日处理水量3.0万吨,污水处理厂的进水水质为化学需氧量(COD)300 mg/l,生物需氧量(BOD)160 mg/l,悬浮物(SS)190 mg/l,氨氮 40 mg/l,总磷 3 mg/l。使用一级B标准.为化学需氧量(COD)60 mg/l,生物需氧量(BOD)20 mg/l,悬浮物(SS)20 mg/l,氨氮 8 mg/l,总磷 1.0 mg/l。

第二章 污水处理系统各构筑物的计算

3.1格栅的计算

格栅是由一组平行的金属栅条制成的框架,斜置在进水渠道上或泵站集水池的进口处,用以拦截污水中大块的呈悬浮或漂渠道上或浮状态的污染物,防止堵塞水泵或管道。在绝大部分污水处理工程格栅是必备的设备。

粗格栅

使用三台规格一样的粗格栅,并列放置,两台同时工作,另一台备用。

3.1.2粗格栅的计算

(1)设计参数

设计流量Q=30000m³/d=1250m³/h=0.3472m³/s

根据流量定Kz=1.4,Qmax=Q![]() Kz=30000

Kz=30000![]() 1.4=42000m³/d

1.4=42000m³/d

设栅前流速V1=0.7m/s,过栅流速V2=0.9m/s

设栅条宽度s=0.01m,格栅间隙b=40mm=0.04m

单位栅渣量w1=0.01m³栅渣/![]() m³污水

m³污水

格栅安装倾角α通常取45°~75°,本次取α=60°

(2)栅前水深:

栅前水深:

根据最优的水力断面公式